Confusing Concepts in Oil Painting: Fat Over Lean

Fat over Lean… Thick Over Thin… Thick Over Lean… Whatever… It’s Time to Get Rid of It

Let’s toss out the concepts of “fat over lean” and for that matter “thick over thin” (or the confused “thick over lean”) while we are at it, and let’s consider the physical structure of the paint.

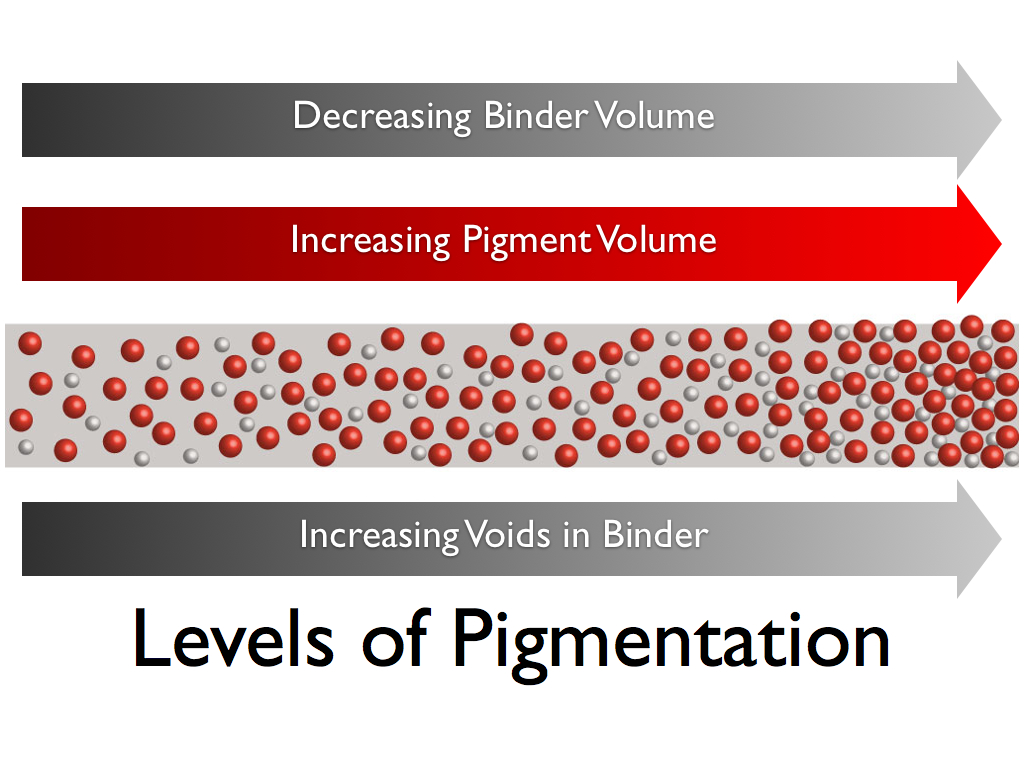

To help you to understand the properties of oil paint, it is helpful to understand the relation between the pigment and oil. One way to think about the relationship between pigment and binder is a brick wall. Every mason knows there is an ideal ratio of mortar to brick. Too much mortar and the wall is weak. Not enough mortar and the bricks fall apart.

The same relationship exists between the pigments and binder in dried paint. We call this relationship or ratio the pigment volume concentration or PVC. Pigment volume concentration (PVC) is the volume of pigment compared to the volume of all solids. If paint has a PVC of 30, than 30% of the total binder/pigment is pigment and 70% is binder solids.

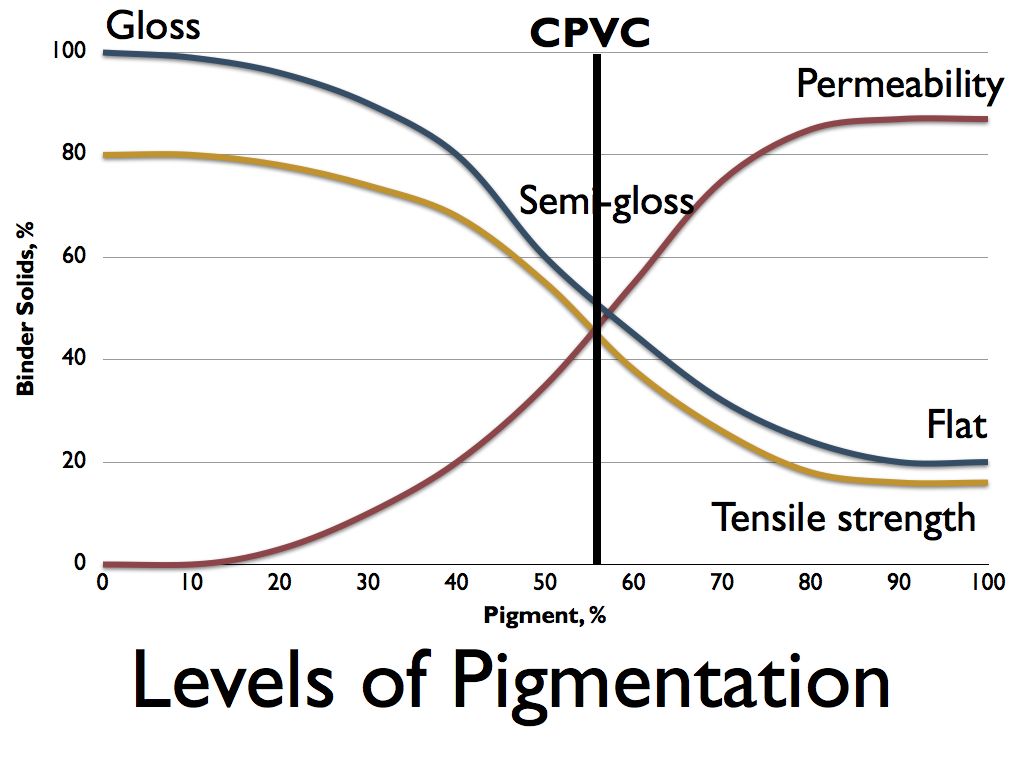

The point at which there is just enough binder to wet pigment particles is called the critical pigment volume concentration (cPVC). For almost all colors this is between 45% and 55% PVC. Films with lower concentrations of pigment have more gloss but as the PVC increases they become increasingly matte. Films with high percentages of pigment are more permeable to moisture and susceptible to solvents. This is because with more pigment, there is less binder to fill the voids between pigment particles. This porosity leaves the film open to the environment. Films with higher pigmentation have increasingly lower tensile strength. (See the graph.)

As the PVC increases past the cPVC, the dried paint film will contain voids. The porosity will increase, moisture vapor transmission will increase, wet hiding will decrease, but dry hiding will increase. As the paint dries, a condition will exist where the paint has too much pigment and too little oil such that the internal voids created will entrap air or solvent in the vapor phase.

Most paint in tubes contain enough binder to wet and envelope pigment particles and so are at about the critical pigment volume concentration or cPVC for that pigment or mixture of pigments. The variation in the pigment volume of particular colors between brands are due to the type of oil used, the amount of oil (some paint makers may choose to make their colors softer or thicker) and the amount of additives used in their formulation.

So the best way to discuss paint is by understanding this relation between pigment and oil which is expressed as the pigment volume concentration (PVC). Oil paint straight out of the tube is in the form of a paste and is usually near its cPVC. Adding oil to paste paint lowers the PVC (low PVC), while adding solvent potentially increases the PVC (high PVC). Hence the ideal paint is a paste paint and this is why the admonition to “apply thick paint thinly” or work with paste paint in thin layers, is the best practice for oil painting.

From this it is clear that paint consists of both liquid and solid components. In the case of oil paint, the liquid component is a drying vegetable oil. The oil undergoes chemical and physical processes that change it from a liquid to a solid, which process is called “oxidative polymerization”. Oil is the binder or glue that holds the pigment particles together and on to a substrate.

You may think of paint as pigmented or colored adhesive. When it comes to adhesion in oil paint, oil is the glue. While many artists believe that mechanical adhesion is most important when it comes to paint, what is more important is “dispersive adhesion”, which does not rely on absorption of the binder or oil into a porous substrate substrate or on surface texture (although they can improve dispersive adhesion) but rather on surface energy and polarity. Hence, paste paint adheres better than paint that has been heavily diluted with solvent (high PVC) even if it is partially absorbed into the substrate, because the latter has less oil or glue to adhere pigment particles to the surface of the substrate.

Oil Absorption

Mixing a pigment with linseed oil and making a paste is a preliminary test applied to pigments, known as oil absorption, that has been in use in a systematic manner for almost a century and perhaps even longer in a less defined manner. This proved to be a practical means to qualitatively characterize the approximate color and texture of pigments quickly with materials and tools readily at hand.

For a long time, the paint industry formulated on a weight basis. In the early part of the twentieth century researchers concluded from a statistical study of house-paint test results that the pigment/binder system should contain at least 28% pigment by volume. Not long after this, reseachers related optimum performance of exterior paints to their critical oil contents, and simple graphical methods for determining this parameter were devised.

From such studies, the relationship known as the pigment volume concentration (PVC) came into use. Studies such as these led to the critical pigment volume concentration (cPVC) concept, and its importance to paint formulation was established.

At the time, drying vegetable oil, alkyds and later acrylic latex were the predmoninate binders used in these studies. These binders envelop pigment particles in a solid film.

Tempera—High PVC Paints

High PVC paints, which include most tempered paints, such as egg tempera, casein, distemper (animal collagen), etc., are unlike paints in which the binder envelops pigment particles, such as oil and acrylic paints. High PVC paints rely on the adhesiveness of the polymers of proteins or polysaccharides to bind pigment particles, but do not cover all surfaces of the particles, and for this reason are naturally high PVC films, because voids are created between pigment particles as the water in these systems evaporate.

These porous films are not only suscpetible to moisture and solvent vapors, but readily absorb liquids. These binder systems are less successful as exterior paint, and usually were limited to interior paint applications. This, however, did not limit their use in fine art painting, since pictures are typically kept indoors.

The cPVC for high PVC systems (tempera paint) will be different from that of oil and alkyd paints. In fact, they share similar characteristics to acrylic paints where the cPVC is typically lower than for oil paint. The problem is determining the cPVC for tempera paint based on the pigment or pigment blend and binder. And secondly how to make the calculation practical for artists.

PVC and Acrylic Paints

cPVC calculated from linseed oil absorption is a good model for oil and alkyd paints because of relatively similar viscosity and wetting characteristics. This is not the case with acrylic paints, which are unable to wet the pigment and flow into voids between the pigment particles to the same degree as linseed oil or solvent-borne alkyds. Acrylic paints invariably have lower experimentally observed cPVC values because of physical limitations during the film drying process imposed by polymer particle size and size distribution, polymer modulus characteristics, and possibly inadequate coalescent solvent. This is also relatable to tempera binders, such as egg, casein, animal collagen, and gums.It may be possible to determine the cPVC for tempera (high PVC) paints based on the porosity index of the paint. The porosity index is a numerical expression of film porosity and can be calculated from the oil absorption cPVC of a pigment composition. The porosity index is the fraction of pigment air voids in a paint film not filled by the formulation PVC binder volume divided by the binder volume required by the pigmentation at cPVC. The equation for acrylic systems is the same as for oil and solvent-borne systems except that the binding power index is included to take the film-forming capability of the acrylic paint into account. This formula may also work for tempera paint.

To state this plainly, cPVC must be calculated for each pigment, particle size and shape, and binder system. So, there is a cPVC for oil paint, another for latex paint (acrylic) and additional ones for each type of tempera binder. Extensive calculations and studies to verify the results have been done for solvent-borne (oil and alkyd) and latex (acrylic, PUD, vinyl, etc.) binder systems.

Relationship to Hiding Power

Hiding power increases with increased pigment volume concentration (PVC), levels off, and then increases again as dry hiding ensues.

Additional evidence of this characteristic of hiding power was found by the Baltimore Paint and Varnish Production Club in a study of the effect of PVC on the wet and dry hiding power of casein paints. The PVC varied from 40.6 to 85.5. In every case involving prime pigments, wet hiding was greater than dry hiding at low PVC. At some intermediate percentage, hiding was equal for both wet and dry film. For high PVC, dry hiding was greater than wet in every case but one, where they were equal at the highest PVC studied.

Excellent explanation. Thanks so much!

George, why do you say that paint diluted with solvent is higher PVC?

As far as I can tell, unless the solvent allows the oil to soak into an under-painting, leaving paint on the surface with a higher PVC, the pigment/binder proportion should remain much the same after the solvent has evaporated. I imagine any evaporating volatile components in the oil would be insignificant as far as PVC is concerned.

(I’m seeking clarification because you are being quoted as saying adding solvent increases PVC at the facebook “Traditional Painting” group.)

Thanks in advance.

Ron Francis.

The solvent does not directly increase the pigment volume concentration (PVC) of pigments but significantly decreases the viscosity of the oil in the paint film. Since oil paint dries rather slowly, this allows the oil to migrate into the substrate below (unless the substrate is non-absorbent), thereby depriving the paint film of oil and increasing the PVC.

Hi George. May I ask, would there be any benefits to the end user by adding the cPVC percentage to paint tubes as a guide to how they have been formulated? For example, a student grade paint would have more fillers (likely) than an artist grade / colourman formulated paint would. Or does each tube regardless of its quality have a cPVC based on how that tube has been made?

Secondarily, would this require a table of pigments/location of pigments used, to then base the cPVC on?

Thanks. I’m just throwing thoughts out there, not an expert!

There are no practical benefits to artists because what may surprise you is that almost all paints have the same cPVC from 45 to 55%. What does matter is the PVC of the paint. This changes based on the actual proportion of pigment to oil. This is something we have considered doing, and certainly we have most of the data already, as should most formulators.